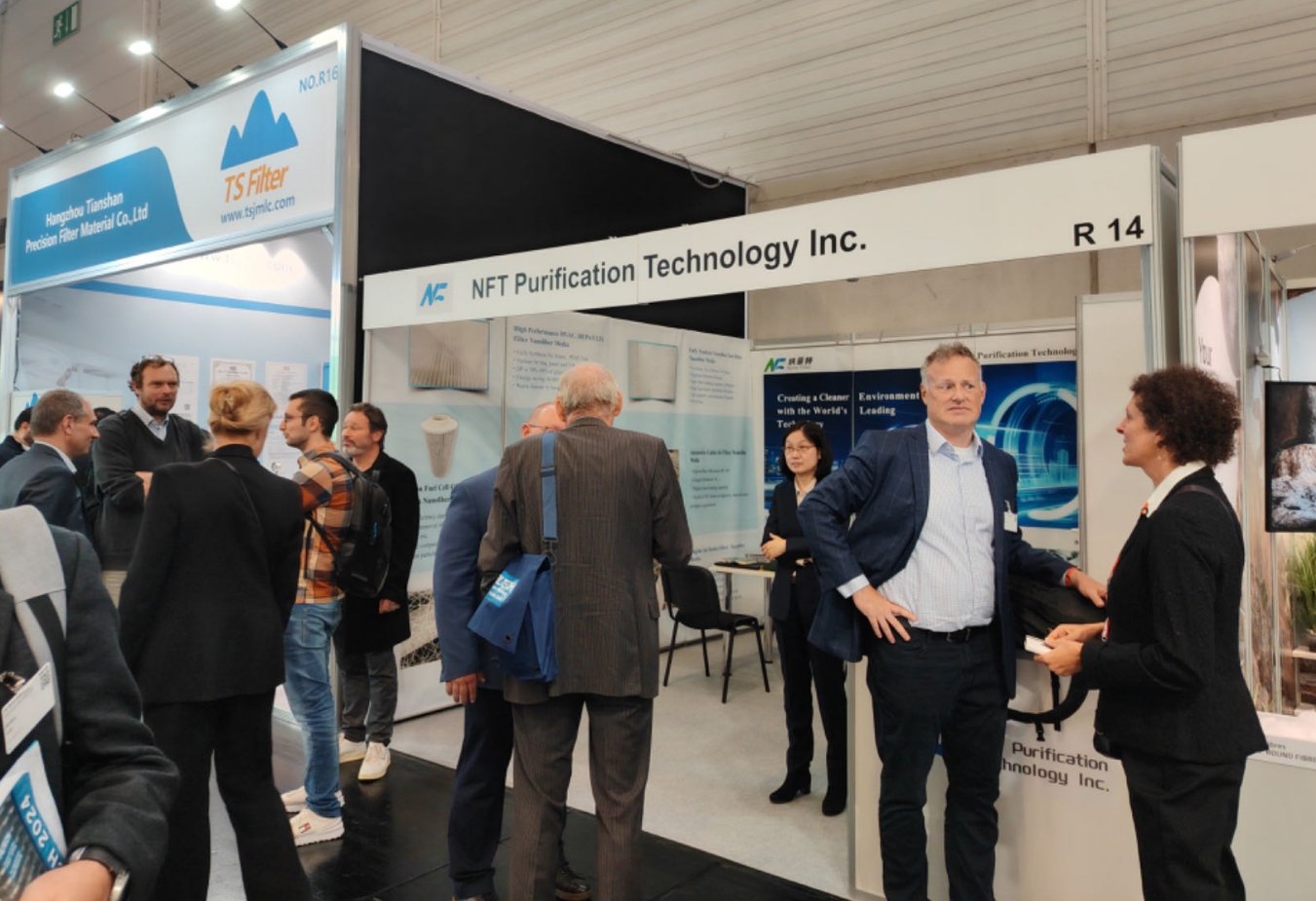

The FILTECH exhibition in Germany is one of the most influential events in the global filtration and separation industry. Since its inception in 1967, FILTECH has continuously led the development of cutting-edge technologies, bringing together the latest innovations and advanced products in the field at each edition.

As a leading technology-driven materials research company, NFT Purification Technology is committed to providing professional and efficient solutions to customers worldwide. At the exhibition, we focused on showcasing a diverse product matrix featuring advanced technologies. Through multiple rounds of communication, we establishing cooperation intentions with many enterprises, and promoting collaborative innovation within the industry.